Impact Resistance ACR: The Guardian of resilience in the plastic industry

Impact-resistant ACR (acrylate impact modifier) is an important additive in the field of polymer materials, significantly enhancing the impact strength of hard plastics such as PVC through core-shell structure design. The elastomer components in its molecular chain can effectively absorb external force energy, endowing the originally brittle plastic products with physical properties similar to "softness overcomes hardness". This "combination of rigidity and flexibility" characteristic makes it a core material in fields such as building materials, pipes, and auto parts.

I. Material Properties and Mechanism of Action

The modification effect of ACR is mainly reflected in three aspects:

1. Energy dissipation: The core layer elastomer absorbs impact energy through deformation, while the shell layer maintains the rigidity of the matrix.

2. Crack blocking: Dispersed phase particles can effectively prevent the propagation of microcracks.

3. Processing optimization: It also has a lubricating effect and improves the flow performance of the melt.

Experimental data show that the notched impact strength of PVC with 5%ACR added can be increased by 8 to 10 times, while maintaining a tensile strength of over 90%.

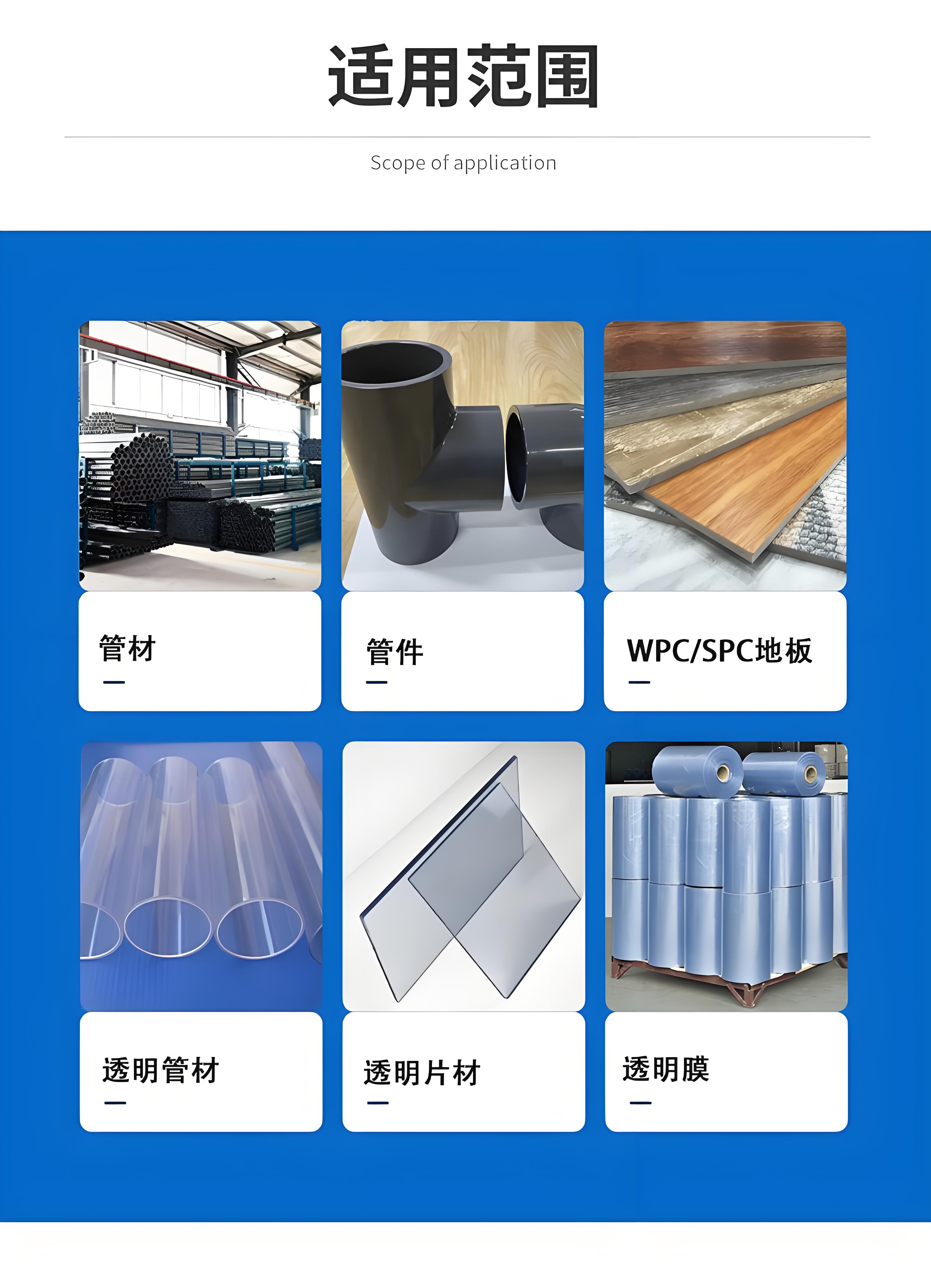

II. Industrial Application Scenarios

1. Architectural field: The weather resistance of door and window profiles has been enhanced, and their service life has been extended by 3 to 5 years.

2. Medical devices: Disposable infusion sets maintain toughness in low-temperature environments;

3. Automotive industry: The dashboard operates stably within a temperature range of -30℃ to 80℃.

Especially in the application of photovoltaic module frames, ACR modified materials have solved the "hot spot effect" problem of traditional aluminum alloy frames.

III. Technological Development Trends

With the tightening of environmental protection regulations, the new generation of ACR is developing towards being free of phthalates and bio-based monomers. The latest nanocomposite ACR developed by a team from the Chinese Academy of Sciences has raised the heat distortion temperature by 15℃ while maintaining its impact resistance. It is estimated that by 2030, the global ACR market size will exceed 5 billion US dollars, and China's production capacity will account for more than 60%.

Shandong AXA Chem Co.,Ltd

June 24, 2025

Leave a Reply

Your email address will not be published. Required fields are marked *