Characteristics and Applications of Impact-resistant ACR materials

Impact-resistant acrylate processing AIDS (referred to as impact-resistant ACR) are indispensable high-molecular modified materials in PVC products. Its core component is methyl methacrylate - acrylate copolymer. Through the core-shell structure design, the outer layer is compatible with the PVC matrix, while the inner elastomer can absorb impact energy. This unique microstructure enables it to increase the impact strength of the product by 3 to 8 times while maintaining the rigidity of PVC.

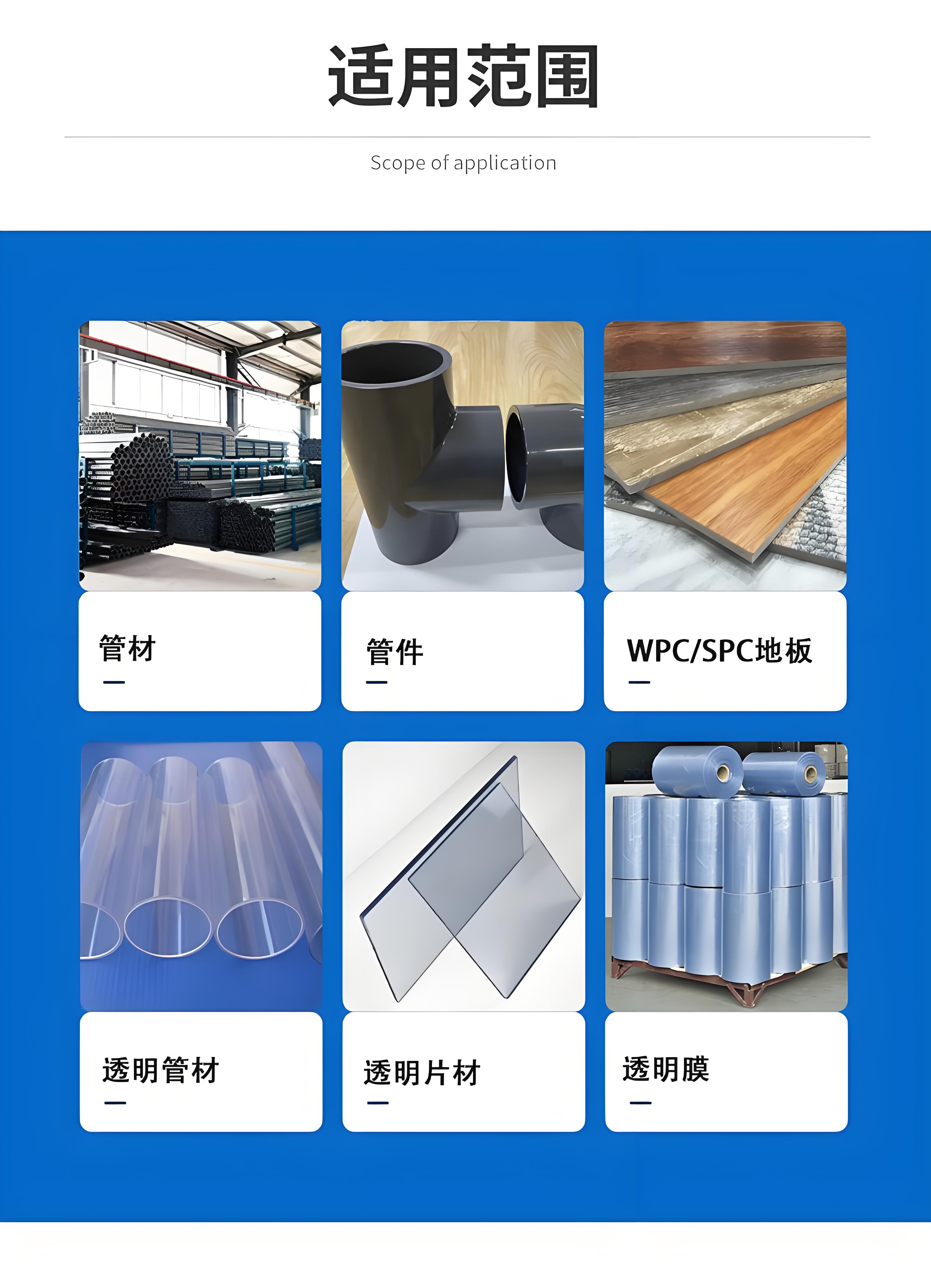

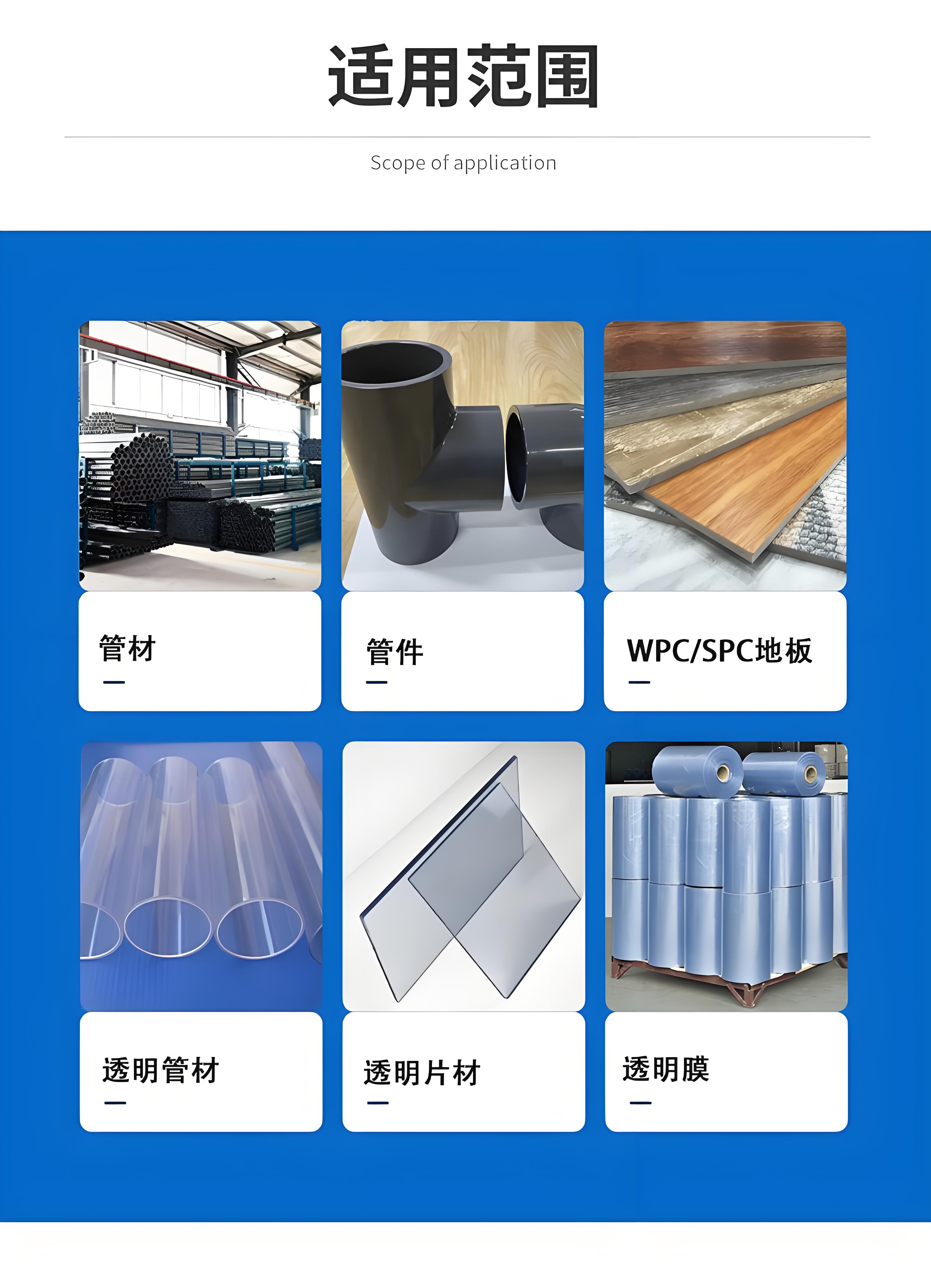

In industrial production, impact resistance ACR mainly plays three major functions: Firstly, it serves as a stress concentration point, dispersing the impact force by inducing silver streaks and shear bands; Secondly, improve the rheological properties of the melt to increase the extrusion molding speed by more than 15%. Finally, it can also work in synergy with stabilizers to delay the thermal degradation of PVC. At present, the annual domestic demand has exceeded 200,000 tons and is widely used in weather-resistant products such as door and window profiles, pipes and pipe fittings.

When we push open the energy-saving window made of impact-resistant ACR, we may not think of the technological code hidden within. From the pipes in the bitter wind and snow of the north to the cable sheaths in the typhoons frequently occurring in the south, these invisible molecular guardians are quietly extending the safety boundaries of modern life - this is precisely the romance of materials science.

Shandong AXA Chem Co.,Ltd

June 17, 2025

Leave a Reply

Your email address will not be published. Required fields are marked *